Since the UK government launched its "green recovery" plans post the COVID 19 pandemic, heat pump technology whether they be ASHP technology or ground source heat pumps has had a central role to play in government policy. Policy documents such as the Heat in Buildings Strategy and The Future Homes and Building Standards have advocated air source heat pumps over traditional heating methods, such as gas boilers.

The overall objective of UK regulation is to harness renewable energy from the air, ground, or water to decarbonise hot water, central heating or underfloor heating production sources.

As discussed at many political debates, the initial investment cost for this low carbon heating technology can be expensive when compared to conventional heating systems, especially for ground source heat pumps. There is also a significant cost gap between gas and electricity prices that can drive up the operational heat pump running costs when compared to gas boilers.

Watch that (Spark) Gap

The spark gap or spark spread refers to the differential between the market price of electricity from a wholesale perspective and the cost of producing that electricity using natural gas.

The spark spread impacts the units of heat produced by electricity in four main ways:

- Dependency on gas for electricity generation: A large volume of the UK's electricity is still generated by using natural gas. Therefore when gas prices rise, the cost of generating electricity also increases, leading to higher electricity prices.

- Infrastructure and grid costs: Heavy investment in upgrading the UK energy infrastructure to support renewable energy sources have resulted in energy prices rising for average households and commercial buildings.

- Renewable energy integration: Renewable energy sources including wind power and solar are projected to lower operating costs, however they require substantial upfront initial investments and grid balancing technology. These operational and start up costs are contributing to higher electricity prices.

- Carbon pricing: The UK has a carbon pricing model to reduce carbon emissions. The costs of this mechanism results in consumers' costs for electricity raising.

The factors above have an impact on the running costs of low carbon technologies from an operational perspective.

At Rinnai UK we can model the capital expenditure, operational expenditure and carbon to demonstrate the environmental benefits and fiscal impact of your next air source heat pump project. Simply contact us today.

How heat pumps operate and how that impacts running costs

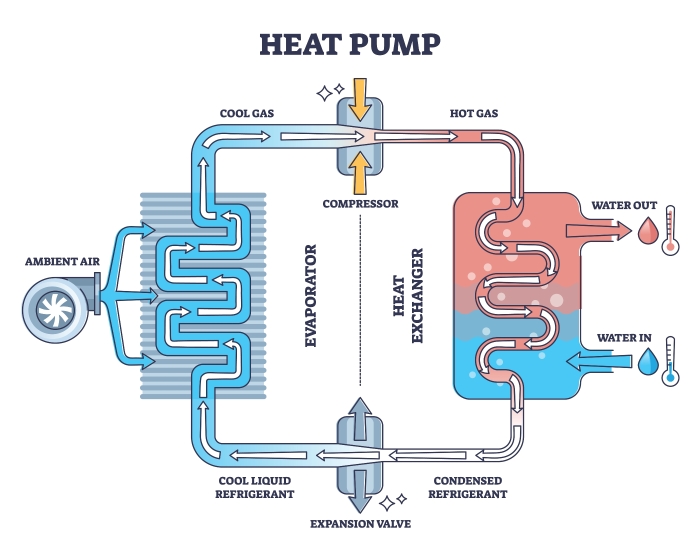

An air source heat pump or ground source heat pump transfers heat from one area to another, utilising thermodynamics. As an example, an air source heat pump would absorb heat from the air and transfer that heat into a cylinder for central heating, underfloor heating and hot water. To perform this process, there are several functions required; firstly a refrigerant is required, this specialised fluid circulates through the system, absorbing and releasing heat as it transitions between liquid and gaseous states.

The system operation begins with the evaporator coil, this is where the refrigerant will absorb heat from the outside environment. As it absorbs heat, the refrigerant becomes gaseous or evaporates. The refrigerant still in gaseous state moves to the compressor - here the pressure is increased which in turn raises the temperature. The gas is now high-pressure as it moves to the condenser coil, within the condenser the gas releases the absorbed heat.

The heating cycle within this low carbon technology is continuous as they transfer heat from the air or ground to a body of water within a cylinder.

This renewable energy technology will run for long periods of time to maintain a consistent temperature within a hot water tank. The running period can be longer in cold weather conditions where the outdoor temperature is lower, meaning that energy usage will be greater.

As these systems are reliant on constant electrical energy usage they can be more expensive when it comes to electricity bills than traditional heating methods such as traditional boilers running on gas.

Understanding the costs of running a heat pump

It is essential to examine both the initial investment costs in terms of upfront costs along with the ground or air source heat pump installation costs and ongoing operational expenditure when considering this technology for your next commercial application.

Firstly, the installation cost of this technology can vary significantly depending on the type of system, the annual heat demand, and regional installation costs.

While the upfront cost may seem high compared to traditional heating systems like efficient gas boilers, it is important to consider the long-term energy and carbon emission savings that an efficient system can provide. Over time, these savings can offset the initial investment and lead to overall financial benefits.

At Rinnai, we model the heat pump efficiency along with full system efficiency to establish the SPF (Seasonal Performance Factor), which gives a truer reflection of the system's financial and carbon performance. Contact us today for more details.

Annual running costs for ground or air source heat pump systems primarily include electricity consumption and maintenance expenses. The efficiency for this technology is often measured by its coefficient of performance (COP), which indicates how much heating or cooling is produced for each unit of electricity consumed.

The greater the COP, means the lower the running costs. As a rough description, a heat pump with a COP of 3 would deliver three units of heating for every unit of electricity used. However, actual costs can fluctuate based on energy prices, climate conditions, and the specific model used.

It is also essential to understand the seasonal performance. As these technologies efficiency ratings differ in cold temperatures, potentially requiring supplementary heat sources such as electric boilers or gas boilers. This can lead to increased operational costs during harsh winters and in colder climates.

Factors that affect the running cost

One of the primary factors affecting air source heat pump costs is the climate.

In geographical locations with less severe winter periods, the technology can operate more efficiently, which in turn leads to lower electricity costs as annual energy will be lower than colder regions.

Conversely, in areas with very cold winters, the air source heat pump may find it difficult to extract adequate heat from the air, which can necessitate the use of auxiliary heating sources that increase operating costs of heat pumps systems.

The type of heat pump and duty also play a role in determining running cost of heat pumps. A properly sized unit is crucial for efficiency, as an undersized system will have to work harder to maintain comfortable consistent temperatures, leading to higher energy consumption. Whereas oversizing the system may lead to cycling on and off too frequently, wasting energy and leading to unnecessary system wear and tear. Additionally, different types of heat pumps, such as air-source heat pumps, ground-source heat pumps, or water-source systems, have varying efficiencies and installation costs, which can affect overall running expenses.

Finally, building fabrics such as loft insulation and cavity wall insulation are important in preventing heat loss, along with the overall energy efficiency of the commercial building, are critical considerations. Well-insulated buildings will retain heat more effectively, reducing the workload on the system which in turn will lower energy costs. If the building has inadequate insulation, air leaks, or substandard building fabric, the heating system will need to run longer to maintain the desired level of warmth, resulting in higher energy bills and carbon.

Therefore, the energy efficiency rate of the building is a major consideration when planning your next project.

Comparing the cost of running efficient heat pumps to other heating systems like modern boilers

When evaluating the cost-effectiveness of modern water or air heat pumps, it is beneficial to compare them to traditional heating systems such as gas or electric boilers for water heaters.

Fossil fuel boilers, for instance, typically have lower upfront costs, but they combust high carbon fossil fuels, which are vulnerable to fluctuating gas prices.

In contrast, low carbon technology, such as electric, can take advantage of renewable energy sources such as green electricity which is increasingly being added to the grid systems. Electricity prices do fluctuate with the costs of gas but are predicted to stabilise long terms.

A major factor aiming at stabilising the electricity cost is government policy. Read more about this here Electricity markets explained | National Energy System Operator

Electric resistance heating systems or electric boilers are easy to install and have simple maintenance regimes but they are much less frugal in terms of energy usage.

Therefore, cost of electricity for running these systems can be significantly higher, leading to increased monthly bills during the heating season. Air source heat pump costs offer a more efficient alternative, providing substantial savings on energy costs over time.

Furthermore, as the aforementioned shift towards more renewable energy sources gathers momentum, the carbon footprint of operating the fleet of heat pump systems in the field is likely to decrease, making it an environmentally friendly option and futureproof solution for the long run.

The importance of correct design

Maximising the efficiency of low carbon systems start at the design stage.

The correct heat generator sizing is vital to reducing air source heat pump running costs and maximising heat energy. However, it does not stop there. It is also critical that cylinder coils and tank sizes are also optimised for optimum heat transfer.

An appropriately sized unit can operate more efficiently, minimising energy consumption.

At Rinnai UK, we offer design support services aimed at maximising environmental benefits. Contact us today to find out more.

Conclusion: Are modern heat pumps expensive to run?

As we have noted earlier, to answer the question of whether heat pumps are expensive to run is reliant on various factors, including upfront costs, energy efficiency, climatic patterns, the type of heat pump deployed and annual energy demand.

While the upfront investment is often much higher than traditional heating systems such as oil boilers and traditional boilers on gaseous fuels. The long-term savings associated with reduced energy consumption and lower long term costs and carbon savings often outweigh these initial upfront costs. It is important to understand the costs of heat pump installations especially when considering ground source or water source heat pump installation, as the excavation work remedial work can be extensive.

Importantly, the environmental benefits of using renewable energy sources make heat pumps and solar panels create an appealing choice for specifiers and consultants having to reduce their carbon footprint.

Understanding the specific nuances of your building envelope is crucial in determining the practical, economical and technical feasibility of your next modern heat pump project. The importance of correct sizing, sufficient insulation and building fabrics play a vital role in system functionality.

Ultimately, heat pumps represent a sustainable and efficient solution for heating, cooling and hot water projects. The investment in this technology could save heating bills in the long run and as the grid system greens, and the "spark gap" is re-aligned lowering the average price of electricity and driving cost savings. Heat pumps should become more affordable whilst contributing to a cleaner and more sustainable energy future.

As the governments move towards more energy-efficient solutions, heat pump technology is primed by governments around the world to play a large role in decarbonising heating and hot water. There are also plans within many governments to reduce the cost of energy in particular the cost of electricity to lower annual energy bills and support heat pump uptake.